We are an independent engineering, fabrication, coating and construction company specialising in the global energy production and processing industries.

Ledwood is a major provider of specialist services to the oil & gas, renewables and power generation sectors

Ledwood have supplied services to the following leading Engineering, Oil & Gas and Power Companies

Call on Ledwood to provide regular or one-off maintenance, to ensure continued efficient running of your plant

Manage significant construction projects, often with a significant process or plant portion with Ledwood

Manage significant construction projects, often with a significant process or plant portion with Ledwood

Ledwood’s in-house engineering and design office with experienced staff provide a complete design package

Ledwood can assist in locating, and and selecting the best suppliers, with a focus on developing value adding relationships.

Ledwood can help with the challenge of the disposal of older plant assets in a way that protects the enviroment.

Ledwood's fabrication capabilities are second to none. We can engineer components to the tightest tolerances.

Ledwood’s paint and protective finishes, at our unrivalled facilities will ensure components are well covered

Ledwood delivers complex engineering projects on time and to budget. Rely on us to manage the whole process, including procurement and supply chain management.

Ledwood can help with the challenge of the disposal of older plant assets in a way that protects the enviroment.

Ledwood’s fabrication capabilities are second to none. We can engineer, fabricate and install components and modules to the tightest tolerances.

Ledwood’s unrivalled paint and coatings facilities will ensure components are properly protected against the elements.

Call on Ledwood to provide regular or one-off maintenance, to ensure continued efficient running of your plant.

Our teams are capable of constructing a wide range of plant and mechanical process installations.

Ledwood’s project management teams can deliver complex engineering projects anywhere in the world.

Ledwood’s experienced in-house engineering and design office provide a complete design package.

SECTORS

Oil and gas remain key fossil fuels. Found across the planet in some of the harshest environments, they are still being discovered, with exploration and the exploitation of new finds demanding complex engineering solutions.

SECTORS

Today’s power industry faces a series of challenges. Tasked with maintaining the supply

of electricity as it continues to grow globally,

the sector also faces growing

environmental challenges.

SECTORS

Today a major growth area, renewable energy technologies are fast developing. Wind and wave power, tidal projects and solar energy are all increasing in adoption and ever larger projects are being developed.

SECTORS

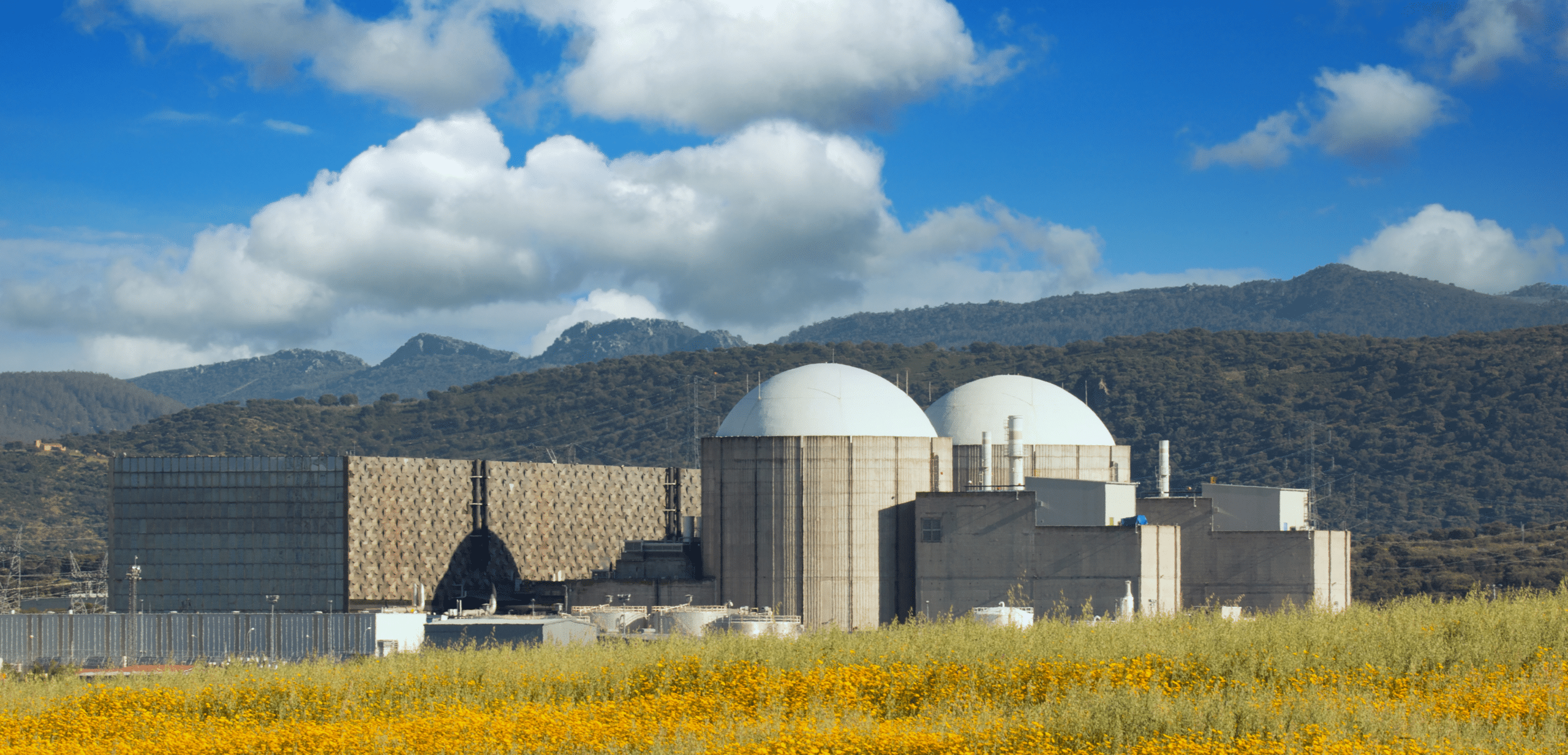

Nuclear is currently viewed as an essential part of the UK’s energy mix providing a high level of clean base load.Ledwood has been working at Hinkley Point C nuclear power station site since 2016 when we were awarded the contract to fabricate the jetty modules. Ledwood has assembled silos, welded tanks and supplied, fabricated and installed embedded ducting and pipework within the conventional island work area of Hinkley Point C.

SECTORS

The liquefication of natural gas enables it to be shipped and stored but keeping gas in a liquefied form presents challenges as it must be maintained at -162degC.

Ledwood provides project management, manufacture and installation of pipework, tanks and mechanical engineering for the LNG sector.

SECTORS

Oil and gas currently supplies three quarters of the UK’s energy consumption but this is predicted to decline to around half by 2050. The use of oil and gas is predicted to decline faster than overall energy consumption leading to a reduced hydrocarbon intensity in the UK’s energy system.

SECTORS

Steel is the most common alloy in the world and is a core part of our work here at Ledwood. The steel industry is increasingly seen as a strategic national asset that has been depleted and needs increasing investment.